5 May 2025

LUBIMAX® 1803 – Engineered for Performance, Optimized for API CF-4

LUBIMAX® 1803 is a high-performance additive package engineered to exceed the demands of API CF-4 specifications, with seamless compatibility across..

READ MORE

17 Jul 2024

The Different Types of Grease and Their Applications

Grease is a semi-solid lubricant commonly used to reduce friction and protect against wear and tear in various mechanical systems…

READ MORE

19 Mar 2024

Frequently Asked Questions About Rust Preventatives

Rust is a pervasive issue affecting numerous industries worldwide, causing damage to valuable assets and infrastructure. Fortunately, rust preventatives present..

READ MORE

26 Jan 2024

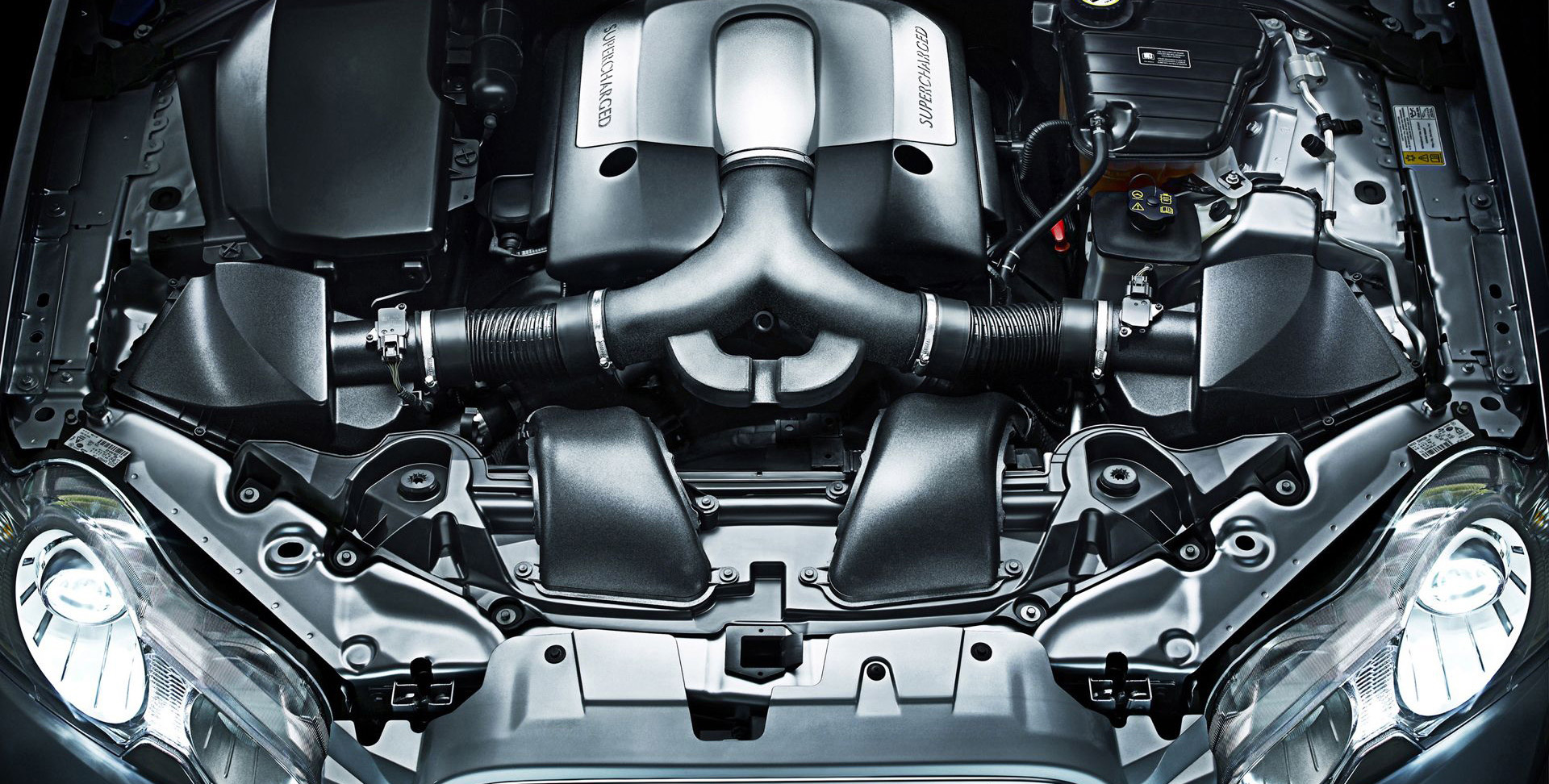

The Role of Engine Oil Additives in Prolonging Engine Component Lifespan

In the world of modern engines, where performance, efficiency, and longevity are paramount, the role of lubricant additives cannot be..

READ MORE

7 Dec 2023

LUBIMAX® Cutting Fluids

Cutting Fluids play a pivotal role in metal processing. They cool, lubricate, inhibit corrosion, and flush away metal chips.

READ MORE

3 Nov 2023

Dispelling Myths: Debunking Common Myths about Grease Additives

LUBIMAX® provides meticulously crafted additive packages and components tailored for the production of high-performance greases across a wide spectrum of applications.

READ MORE

12 Jun 2023

Techno-Commercial Session – Automechanika Istanbul

Our team recently attended Automechanika Istanbul, a globally renowned trade fair for the automotive aftermarket industry. This year’s event, held..

READ MORE

9 Mar 2023

NLGI 25th Lubricating Grease Conference

NLGI recently celebrated its Silver Jubilee 25th Lubricating Grease Conference from 3rd to 5th March at the Grand Hyatt Gurgaon..

READ MORE

5 Dec 2022

Techno-Commercial Session 2022

LUBIMAX® hosted a Techno-Commercial Session on 23rd November at Automechanika. There were 6 featured speakers from Kemipex, INEOS, BASF and..

READ MOREGet in touch

Get in touch with us! or feel free to drop us a note if you wish to learn more about any of our services

Phone

+65 6694 8800Request the LUBIMAX® Product Selector Guide