Along with offering high performance fully developed additive packages, LUBIMAX® also supplies various additive components to help formulators create distinguished performance properties in finished products. These additive components can be used in a wide range of applications to improve lubricant performance and to meet specific needs.

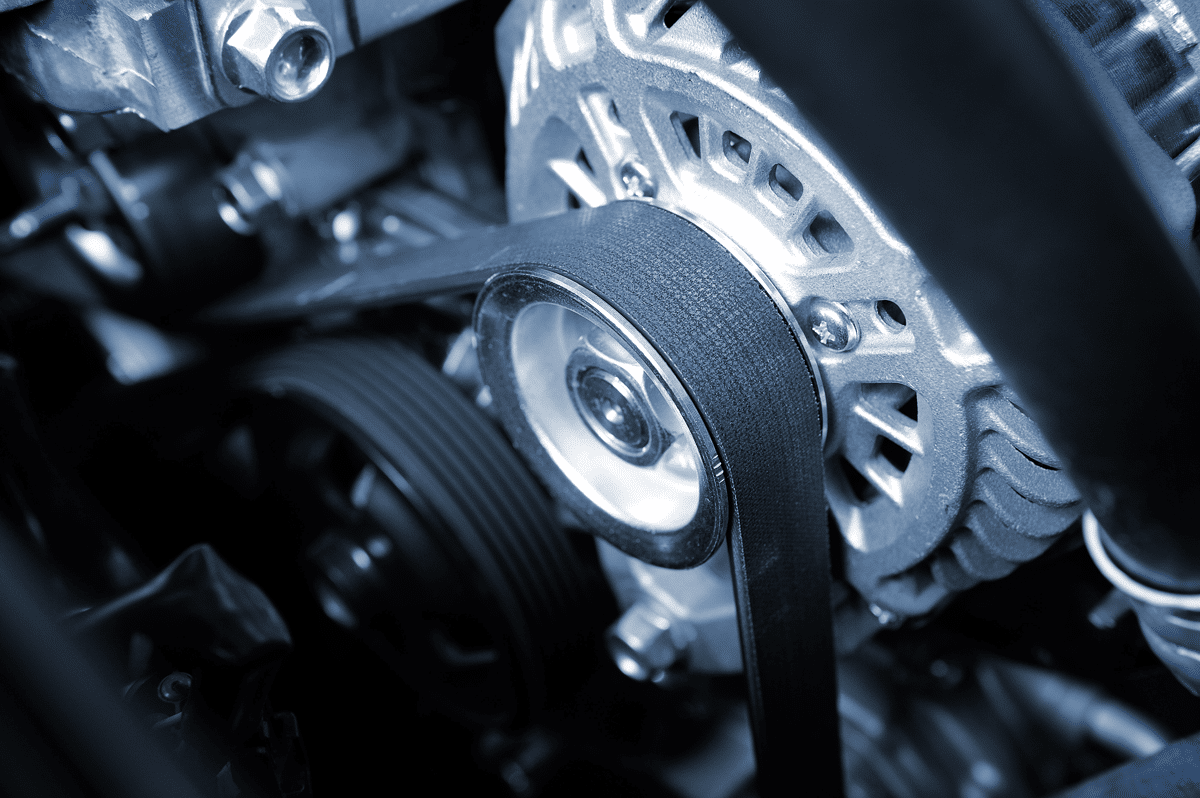

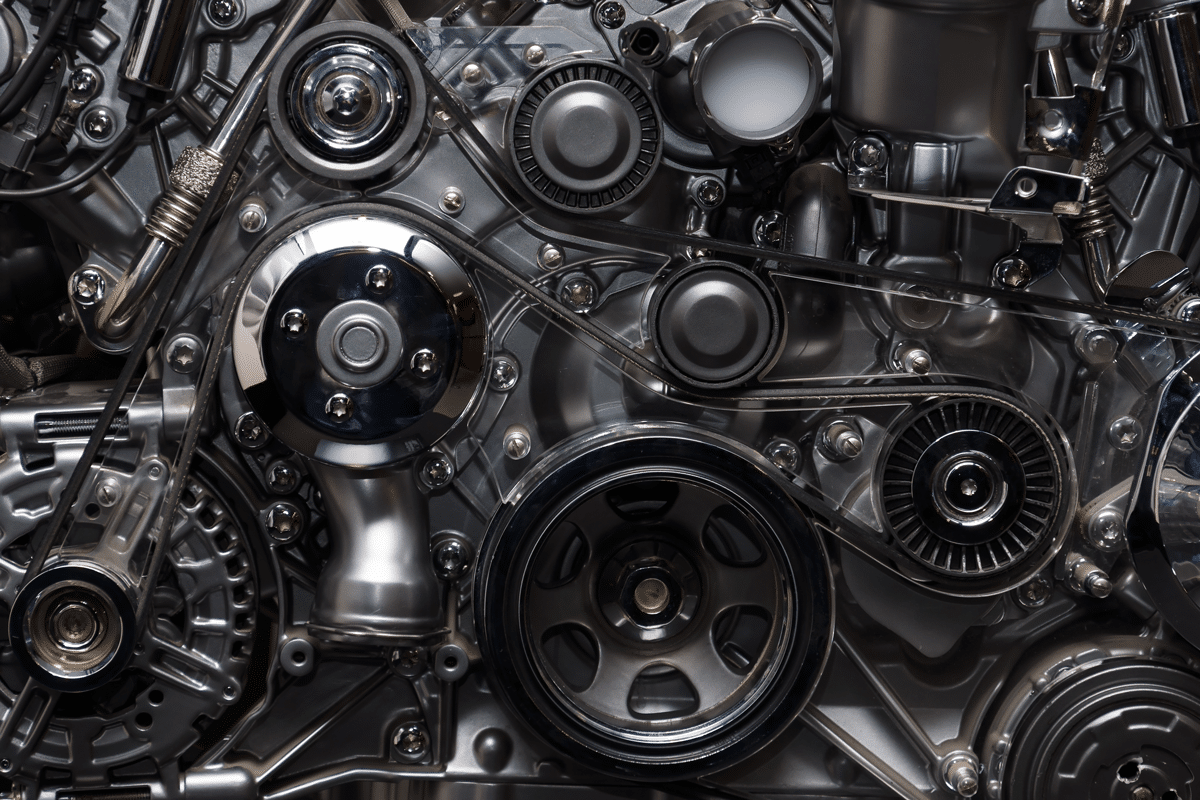

LUBIMAX® offers high-performance Polyisobutylene (PIB) based dispersant additives with different molecular weights and Base Numbers (BN). These products provide excellent dispersion properties in a variety of applications, especially in gasoline and diesel engines where the lubricant is exposed to combustion by-products. These additives can be used in transmission fluids, gear, and industrial oils formulations as well. Typical characteristics of LUBIMAX® Boron-free and Boronized PIB-based dispersants are tabulated below. Boronized PIB-based dispersants are multifunctional additives, and they impart antiwear and antioxidant properties to the finished lubricants.

LUBIMAX® offers a wide range of detergent additives that can be used in the formulation of various lubricants. These additives are designed to meet detergency requirements in both automotive and industrial applications. LUBIMAX® detergents cover a variety of Base Number (BN) levels; they can be neutral, overbased or ultra overbased. Five categories of LUBIMAX® Detergent products are presented:

Calcium and Magnesium Sulphonates are well-known to form micellar structures and impart key functions to lubricants. Calcium Alkyl Phenate detergents are highly thermally stable; this property makes them suitable for use in HLPD hydraulic oils, marine oils, and high-duty diesel engine oils. These products play multifunctional additive roles that impart detergent, antioxidant, anti-corrosion, and antiwear properties to lubricants.

LUBIMAX® antiwear additives are mainly Zinc Dialkyldithiophosphate (ZDDP) based products that are specially designed to be used in various automotive and industrial applications. These additives are primary, secondary, and primary-secondary ZDDPs prepared from various types of alcohols.

LUBIMAX® offers customized antiwear additives with different thermal stability, hydrolytic stability and antiwear protection properties. Based on the priority of the performance properties in the finished products proper grade of these products can be utilized in the formulations and act as an effective additive.

LUBIMAX® offers a wide range of Rust Preventatives that effectively protect metal parts from rust and corrosion during storage and shipment. These additives can be used to produce high-performance oil-based, solvent-based, or waterbased rust preventive fluids meeting the requirements of different applications.

By forming protective films, these rust prevention additives provide superior protection for metal surfaces that are stored in environments with high rust potential. Depending on the type of carrier fluids and the additive, various types of films, such as dry-to-touch, waxy, greasy or oily, thick, thin, or ultra-thin films, can be formed. Then, protective films can be removed with solvents and/or alkaline cleaners, depending on film type and thickness. Some of these packages also provide demulsibility, water displacement, enhanced salt spray protection, and non-staining properties.

Finished rust-preventive products that provide maximum long-term or temporary protection of the metals can be formulated by proper rust prevention additives selected based on several parameters. Some of the most important parameters are storage and shipment environmental conditions, storage duration, and additional properties such as demulsibility/emulsibility, water separation, etc.

THIN FILM

These products form dry-to-touch, greasy or oily, thin films for prolonged indoor protection. Thin film products are diluted in solvent, oil, or combination.

ACID ATMOSPHERE

These products provide excellent protection of metals against acidic environments by forming virtually invisible protective films. Acid atmosphere products are diluted in oil, solvent, or combination.

HEAVY DUTY

Heavy-duty products form a visible, thick, dry-to-touch, greasy, or oily film for outdoor protection. They are diluted in oil, solvent, or water.

EMULSIFIABLE

Emulsifiable products form an ultra-thin protective film. They are diluted in oil or directly into water to formulate concentrates. The concentrates are further diluted with water by the end user.

LUBIMAX® offers additive components that can be used in the formulation of various metalworking fluids. These additive components improve lubricant performance, emulsification, lubricity, corrosion inhibition and impart desired properties to the finished fluids.

LUBIMAX® metalworking rust preventives effectively protect metal parts from rust and corrosion during storage and shipment. These additives can be used to produce high-performance oil-based, solvent-based, or water-based rust preventive fluids meeting the requirements of different applications.

LUBIMAX® offers high-performance pour point depressant (PPD) additives that efficiently lower the pour point temperatures of various mineral base oils with different wax contents. These additives can be used in formulations of various lubricants such as diesel and gasoline engine oils, automotive gear oils, industrial oils such as hydraulic oils, gear oils, compressor oils, etc.

To opt for the best PPD for the finished product formulations, the performance of the PPD in the pour point depression of the used base oils should be checked to identify which PPD is the most suitable choice.

LUBIMAX® offers specially designed antioxidant additives that can be used to formulate various automotive and industrial lubricants. LUBIMAX® antioxidants help extend life and improve the performance of industrial and engine lubricants. These additives provide longer equipment life and fewer maintenance shutdowns in industrial applications. Automotive lubricants benefit from longer drain intervals and improved fuel economy by using LUBIMAX® antioxidants.

LUBIMAX® offers specially engineered additive components for producing high-performance greases in a broad range of applications. These products improve grease performance effectively and impart desired properties to the finished products.

Read More

LUBIMAX® also supplies various additive components to help formulators create distinguished performance properties in finished products. These additive components can be used in a wide range of applications to improve lubricant performance and to meet specific requirements, products such as antifoams, demulsifiers, tackifiers, etc.

Get in touch

Get in touch with us! or feel free to drop us a note if you wish to learn more about any of our services

Phone

+65 6694 8800Request the LUBIMAX® Product Selector Guide